Turning Biogas Plants into Profitable, Future-Proofed Assets with Anessa AI

In the renewable energy space, especially the biogas sector, ambition isn’t the problem; efficiency is. More projects are getting off the ground, more capital is flowing in, and the pressure to perform well as well as visualize the value of your investment is rising. Yet far too many anaerobic digestion plants are built with a seemingly good opportunity without an understanding of the long-term implications of technology decisions or risks, like oversized digesters, underutilized heat, or feedstock that doesn’t match the assessment model. And it’s not always the tech that’s missing. Sometimes, it's simply the foresight.

At Anessa, we believe that biogas projects deserve better planning, tighter execution and more resilient planning before as well as after commissioning, and that’s where Anessa’s AI suite of products and digitalization delivers.

Planning Smarter from Day One: Why Simulation Pays Off

Biogas plants are complex. Between biology, engineering, feedstock variability and financial expectations, there are a lot of expectations to manage and explain to potential investors. Our Anessa AD•A platform gives project developers the ability to test, iterate and stress-test scenarios before construction. Using the power of artificial intelligence in biogas planning can be the foundation for the proper evaluation of potential risks and the long-term impact of decisions made at the beginning of the project.

With AD•A, you can:

Predict real-world performance through dynamic modelling using Anessa digital twin

Identify bottlenecks from feedstock availability to RNG and digestate quality

Avoid CAPEX waste from oversized digesters or overestimated biogas yields

Validate the biogas project’s ROI potential with real numbers

Here’s a real-world example of how Anessa AD•A helped Leyline Renewable Capital uncover critical data discrepancies in a biogas investment. When evaluating a farm-based biogas project, Leyline Renewable Capital faced conflicting data from multiple providers, resulting in a risk to the accuracy of their due diligence. Using Anessa AD•A, the team was able to efficiently validate key project assumptions and uncover a significant overestimation in projected biogas output. Anessa’s advanced analytics revealed that the initial estimates were overstated by 53 million ft³ of biogas annually, equivalent to around 30,000 MMBtu per year. This insight helped prevent a $2 million annual revenue overestimation, allowing Leyline to make a more informed and confident investment decision.

By bringing clarity and accuracy to complex project data, Anessa played a critical role in supporting Leyline’s commitment to smart, sustainable investment in the biogas sector.

Anessa AD•A platform screenshot

From Data to Dollars: Optimizing Biogas Operations with AI

Now that you have a great design, operational success comes down to one thing: consistency. Feedstock changes. Seasons change. Energy Market Uncertainties. Contracts shift. But the business and AD plant still need to hit their numbers.

That’s why we built Anessa AD•O, our AI-powered operational optimization platform.

Anessa AI works like a real-time control tower, helping plant operators:

Simulate different feedstock recipes

Maintain nutrient balance and minimize energy losses

Optimize for Carbon Intensity (CI) scores to maximize credits

Adapt to fluctuating feedstock availability or prices

Plan long-term feedstock contracting strategies with confidence

Identify potential suboptimal conditions in advance.

Whether you're aiming for net-zero goals or maximizing CFR credits, LCFS and D3 RIN revenue, Anessa AD•O gives you the tools to respond, refine, and improve.

In one of the retrofit projects, Anessa optimized an RNG plant in North America by enhancing key areas such as feedstock supply planning, process design, and RNG utilization. The plant’s baseline production was 180,000 GJ/year with a carbon intensity (CI) score of 0 gCO₂e/MJ. Following Anessa’s optimization, the CI score improved to -50 gCO₂e/MJ, and RNG production increased to 230,000 GJ/year. These improvements resulted in greater GHG reductions and an additional 1.5 million CAD in annual revenue for the plant.

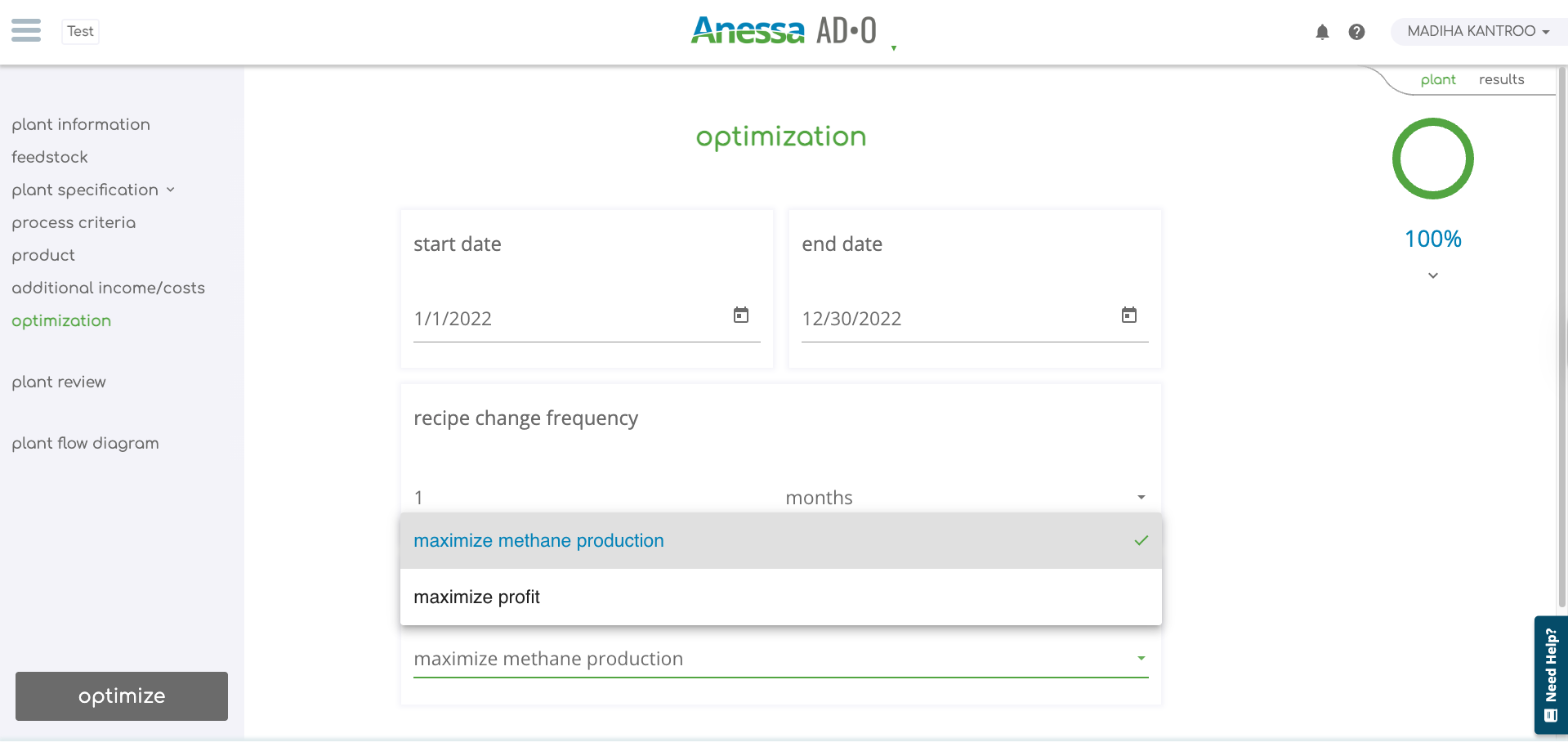

Anessa AD•O platform screenshot

Anessa AD•O platform screenshot

Digitalization Is Not a Trend, It’s a Necessity

Whether it's Canada’s Clean Fuel Regulations (CFR), California’s Low Carbon Fuel Standard (LCFS), the U.S. Renewable Fuel Standard (RFS), or the EU’s Renewable Energy Directive II (RED II), the message is clear: the future of energy is low-carbon and biogas is stepping into the spotlight and clear data showing the benefits of the industry is a cornerstone to biogas’ widespread utilization.

Countries like France and Germany are doubling down on renewable natural gas (RNG), tightening emissions tracking and sustainability requirements. But meeting these evolving standards isn’t just about compliance; it’s about data transparency. To succeed in this next chapter, biogas projects and businesses must go beyond traditional practices. They need to be data-driven, adaptable and built to last. This is where digital tools like Anessa AI come in, helping teams make smarter decisions, stay ahead of policy and build operations that are ready for whatever comes next.

By combining predictive modelling, digital twin simulations and real-time AI optimization, Anessa equips stakeholders with a future-proof suite, one that empowers better decision-making from feasibility through operation. This means:

Faster, data-driven project approvals

Confidence in CI score estimation, outcomes, and compliance

Reduced CAPEX and OPEX through simulation and optimization

Future scalability for changing feedstocks, regulations and revenue streams

Anessa isn’t just helping build biogas plants; we’re helping build resilient, profitable, low-carbon energy businesses that are ready for the future.

Farough Motasemi, CTO, Anessa

“The future of biogas lies in precision, adaptability, and data-backed decision-making. That’s why digitalization is no longer a nice-to-have; it’s a critical enabler of performance and profitability. At the heart of this transformation is the digital twin: a real-time, AI-powered model that mirrors the biological, technical, and economic behaviour of a biogas plant. When paired with advanced analytics and machine learning, it becomes a powerful tool for modelling complex biological processes, predicting outcomes, and identifying optimization opportunities before issues arise.

At Anessa, we’ve built a technology platform that supports biogas projects at every stage, from feasibility assessment and financial modelling to operational planning and live monitoring. Whether it’s evaluating feedstock potential, designing for maximum energy recovery, or adjusting recipes in real-time for better CI scores, Anessa bridges the gap between biology, engineering, and business intelligence. Anessa is proud to help operators, developers, and investors make that leap with technology that’s built for the complexity and opportunity of the biogas industry.”